Manufacturing Software Development Services

There is now a surprising number of operational details in the manufacturing industry that you can automate or optimize with custom software – both on the factory floor and outside. The big bundle of challenges that inventory management, resource allocation, machinery maintenance, compliance, sales and logistics present is easier to disentangle with interconnected digital tech.

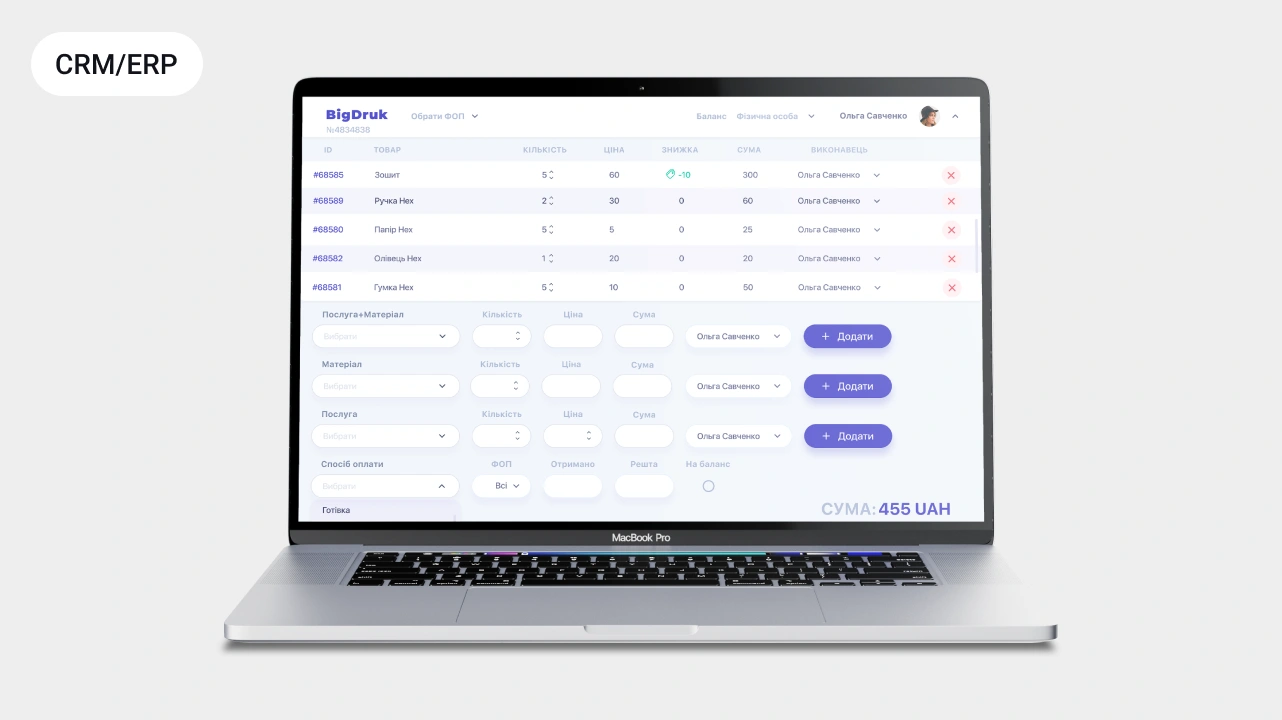

We provide tailored software solutions for manufacturing companies that go beyond the traditional ERP system scope and incorporate AI and IoT in strategically defined use cases to increase efficiency and reduce waste along the way.

Manufacturing Software Solutions and Services We Provide

Benefits of Custom Manufacturing Software

Improving efficiency by addressing “minor” details

While out-of-the-box solutions exploit the well-known ways of raising efficiency by automating what’s usually automated, each company has a set of unique processes or transitional operations that, if automated, can yield even better productivity. Custom software allows to reach these exact spots.

Reducing waste and optimizing resource use

Custom software solutions using internal data from reporting and/or sensors can help apply numerous methods of reducing scrap amounts and using resources sparingly: scheduling, dynamic task reallocation, predictive maintenance, and more.

Possibility of data-driven decision making

Tailored systems collect exactly the data that is needed to establish an actionable data policy, and which can be also “fed” to AI algorithms for working with vast datasets and complex interdependencies.

Reconciling production with supply and demand

Production is notoriously inert compared to demand fluctuations, so every possibility of reconciliation between the two in real-time has the potential to save large sums and latch onto market trends. Technology helps cut the red tape between departments and reports and streamline communication along the entire supply chain, from vendors through the factory floor to customers.

Facilitated compliance and sustainability

Properly selected or designed solutions can be helpful in ensuring compliance with regulations and overall sustainability of the production. The exact arsenal of tools needed, from vendor portals to corporate LMS and QC systems, and the way they interconnect, are defined for each company individually, so custom solutions make a lot of sense.

TECHNOLOGIES

.NET

React

Node.js

Angular

Vue.js

MySQL

PostgreSQL

MongoDB

RabbitMQ

Docker

Kubernetes

Redis

Identity Server

Python

TensorFlow

PyTorch

PROJECT DISCOVERY

We start with a consultation and research of the current workflows to pinpoint the opportunities for optimization.

This allows us to suggest the scope and roadmap for the perfect solution.

SOLUTION DESIGN

This is where the architecture, tech stack, and UX are designed to match the business-side vision, and embodiedin a PoC or prototype to validate the functionality of the software.

DEVELOPMENT & INTEGRATION

At this stage, software developers work iteratively, with feedback cycles, to build the modules of the solution and integrate them with legacy systems and third-party platforms where necessary.

QA, DEPLOYMENT, TRAINING

Here, we test the solution (functionality, performance, security), and after validation, deploy it and provide training for target users if needed, so that proper adoption is ensured.

MAINTENANCE

After deployment, the software is continuously monitored for performance, reliability, and evolving business needs. Regular updates keep the system aligned with production changes, new equipment, or regulations.AI Software Development for Manufacturing Businesses

We apply our expertise in AI/ML development to manufacturing solutions with a sober, precise approach – implementing artificial intelligence exactly where it yields actual value, and never for its own sake. In our experience, artificial intelligence works best for automation, product quality control, and supply chain optimization, as well as different cross-combinations of these domains, since this is where most valuable data flows are. Accordingly, we always design these solutions for maximum positive impact.

The solutions we develop include:

- Predictive maintenance systems

- Computer vision for quality inspection and defect detection

- Demand forecasting and inventory optimization models

- AI-driven production scheduling and workflow optimization

- Intelligent supply chain management and logistics optimization

- Energy consumption monitoring and efficiency analytics

- Natural language processing (NLP) assistants for operator support

- Generative design for product and process innovation

Our Approach

Company- and process-specific (but scalable) tools

In our experience, a manufacturing business’ identity is defined by more than just the type of goods produced – and that impacts the type of tools they will benefit from. This is why we base every solution’s design on a deep, ground-level understanding of the actual process as described by the people who are involved in it.

Pragmatic empathy in UX for better adoption

The best software is that which is willingly adopted by its users and brings clarity instead of chores. The tools we design are created by considering what the moments of actual use feel like to those operating them. In this way, we bring the power of IoT sensors, AI and ML, and multiple integrated systems to the user’s fingertips.

Careful management of data flows as groundwork for AI

As the industry is now starting to adopt artificial intelligence, which, in turn, needs quality data to learn and operate, we build everything to function not just as a tool in and of itself, but also as a valuable supplier of data, a part in the informational ecosystem of the company – while also ensuring security and compliance.

To find a perfect solution