Warehouse Management Software Development Services

Warehousing is often the one aspect of logistics that has to adapt to the constraints posed by the other ones. Warehouse locations frequently depend on transportation routes, their size depends on the demand and inventory management tactics, and so on. All this spurs innovation in the way warehouses operate, and by now, warehouse management software allows businesses to optimize almost every detail.

Different businesses and goods call for different types of warehouse management systems. A good WMS can not only reduce storage costs by up to ⅓, but also help improve the efficiency of employees doing the picking and packing, as well as order fulfillment processes. In other words, modern warehousing software yields ROI fast and spectacularly so. With Lionwood’s expertise, you can have a custom WMS built for your unique needs to maximize the output.

Integrated, Harmonized Warehouse Management Systems

For the warehouse management software to work its “magic”, it needs to be integrated perfectly into the digital ecosystem of the company. While the list of the possible functionalities that modern warehouse management solutions have is growing each year, ultimately, the key to success is how harmonically they are orchestrated into a single whole, with data flowing seamlessly between WMS solutions and other existing systems, and all warehouse processes tied together, from on-site IoT and robotics to analytics and reporting. Our approach to warehousing solutions is to enable this sort of symbiosis between warehouse operations, transportation, fulfillment, and more on all levels, with scalability in mind.

WMS for Omnichannel Fulfillment

As eCommerce (both B2C and B2B) is becoming more prevalent, with mixed models emerging, too, the number of sales channels to deal with is becoming a multi-variable problem. Being able to handle multiple channels and track inventory levels in real time accordingly is an aspiration many businesses now have – and warehouse management software can enable it. In addition, a good warehousing platform can instantly update and harmonize data from multiple warehouses at once, something that previously required a full-time employee or several of them. The result is a system where whatever happens at a single warehouse, whatever transaction occurs on an eCommerce platform, the response is instant and accurate. Even in case of reverse logistics.

ROI-Oriented Use of AI and IoT in Warehouse Software

Artificial intelligence and Internet of Things are relative newcomers to the logistics industry, but they are already recognized game changers in warehousing. Being able to monitor warehouse data like temperature, humidity, or shelf space with sensors and computer vision, and then have algorithms analyze that information has spared the likes of Amazon billions of dollars. Now this tech is becoming available to the broader business circles, and the only remaining question is how exactly to implement it with maximum effect? Our expertise focuses on balancing the approach between solving pinpointed challenges, and paving the way for larger-scale adoption in the future, if need be.

What Custom WMS Software Could Do for Your Business

Benefits of custom Warehouse Management Systems

When it comes to warehousing, the differences between businesses are so unexpected that it’s difficult to put a certain company into a particular category. A business operating one relatively small warehouse with heavily regulated products that require special conditions versus one that has multiple warehouses scattered across different locales, selling FMCG with same-day delivery promise will obviously require different warehouse management software solutions.

Yet out-of-the-box solutions are naturally developed for large categories of businesses. If yours fits perfectly into one of such target user groups, finding a good WMS is easy. But in many cases, custom warehouse management software development services are a better option.

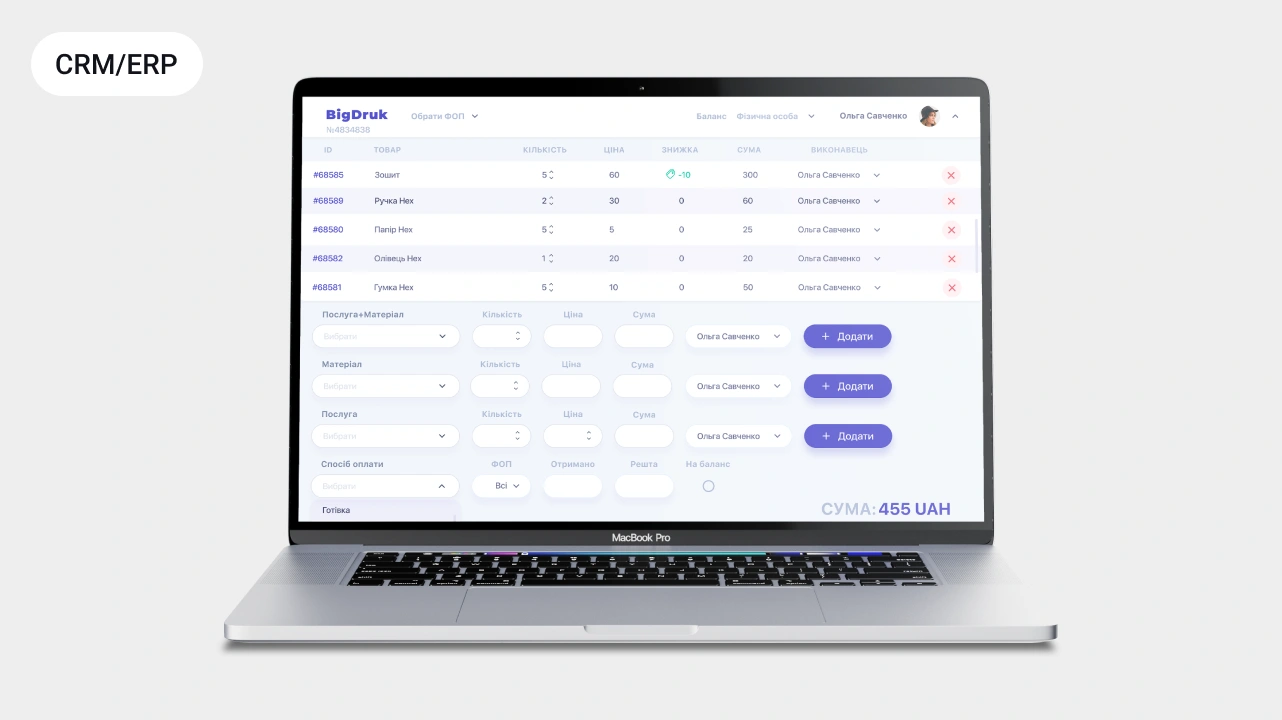

One of such cases is when your business has established unique processes that need to be preserved as a corporate know-how – and software should better not dictate how to work. As a team of custom WMS developers, we’ve also seen companies that choose to go for tailored platforms for scalability. It is also a good idea to check what external integrations (especially with legacy systems or ERPs) you will need, since a WMS functions best when it’s connected to the rest of the infrastructure. You can count on our expertise in helping define and shape your custom WMS or other management tools to fit your organization’s needs precisely.

Warehouse Management System Development Services We Deliver

-

Custom WMS development

Our team of experts can design and build a tailor-made warehouse management system that will match your business’ operational models, workflows, and scaling needs, with the exact functionalities that will yield maximum ROI.

-

Warehouse software consultation

You can contact us for expert advice and strategic planning to optimize your warehouse software solutions and improve overall warehouse efficiency.

-

Integrations (API, EDI)

A common and important part of software functioning, integrations ensure the seamless exchange of data with ERP, portals, financial tools, and more. We work with both API and EDI integrations to ensure interoperability on different levels.

-

WMS architecture planning

Based on our previous experience in the industry, our experts can provide a comprehensive architectural blueprint, outlining the structure, components, and workflow of your WMS for optimal performance and scalability.

-

AI Modules

There are several major points of application of AI in warehousing, from computer vision to automation to analytics. We have a team of AI experts with industry knowledge that are ready to take on the development and training of these models.

-

WMS mobile apps

Not everyone in a warehouse is sitting at a laptop, so our experience in warehouse mobile app development often helps supplement the WMS with on-the-go access for employees, with different user roles having their own intuitive UX.

-

Warehouse IoT systems development

Increasingly often, we are building Internet of Things (IoT) systems for warehouses that involve smart sensors, connected devices, and real-time data tracking and analytics.

-

Legacy System Reconciliation

We can bring the new software we build for you in harmony with the legacy systems that are reasonably kept in place, while upgrading the latter if necessary. This ensures compatibility of new tech and new capabilities with the software you are already using to avoid overinvestment and disruption.

Why Choose Us as a Warehouse Management Software Development Company

Warehouse Management System development company with profound industry understanding

Our specialists have worked with projects aimed at the various participants of the logistics process, from warehousing to end customers, and possess the best practices in applying the relevant tech stack to multiple user scenarios.

Agile development practices embedded in the WMS development process

You can be confident that your logistics software solution will be delivered on time, while leaving room for flexibility and further customizations. Our strong point is marrying Agile with warehouse management.

Superior WMS maintenance

Lionwood provides extensive maintenance services to ensure the software stays in line with the overall ecosystem and infrastructure.

Scalable and customizable warehouse management systems

With Lionwood, you can be reasonably sure the logistics software you receive is built with the future in mind – we take care to use the technologies that will allow you to plug in further users, modules, and functionalities as you go.

To find a perfect solution